Architecture and Engineering professionals understand the importance of survey control in 3D Laser Scanning. But, the real question is how laser scanning information can be linked to Survey Control. A Survey Control charts out vertical and horizontal positions for supplementary surveys. They provide a basis for the accuracy of subordinate and subsequent surveys. These secondary surveys depend on position and control of relative accuracy.

3D Laser Scanners produce highly-detailed images and measurements of images through the use of LIDAR technology. These distances and locations create a Point Cloud file. 3D Laser Scanning delivers a myriad of opportunities for Architects, Engineers, General Contractors, Surveyors, Owners. It helps them analyze, assess, and track data taken from a physical space.

Apart from delivering high visualization and project clarity, 3D Laser Scanning helps save money and time coupled with enhanced decision making. Some of the applications of 3D Laser Scanning include – evaluating existing conditions, track construction progress, carry out assessments, document as-built conditions, etc. Furthermore, 3D Laser Scanning establishes a rock-solid platform to improve project and asset information management.

The benefits of adopting Laser Scanning with survey control assists engineers, managers, architects, and onsite personnel with enhanced adoption.

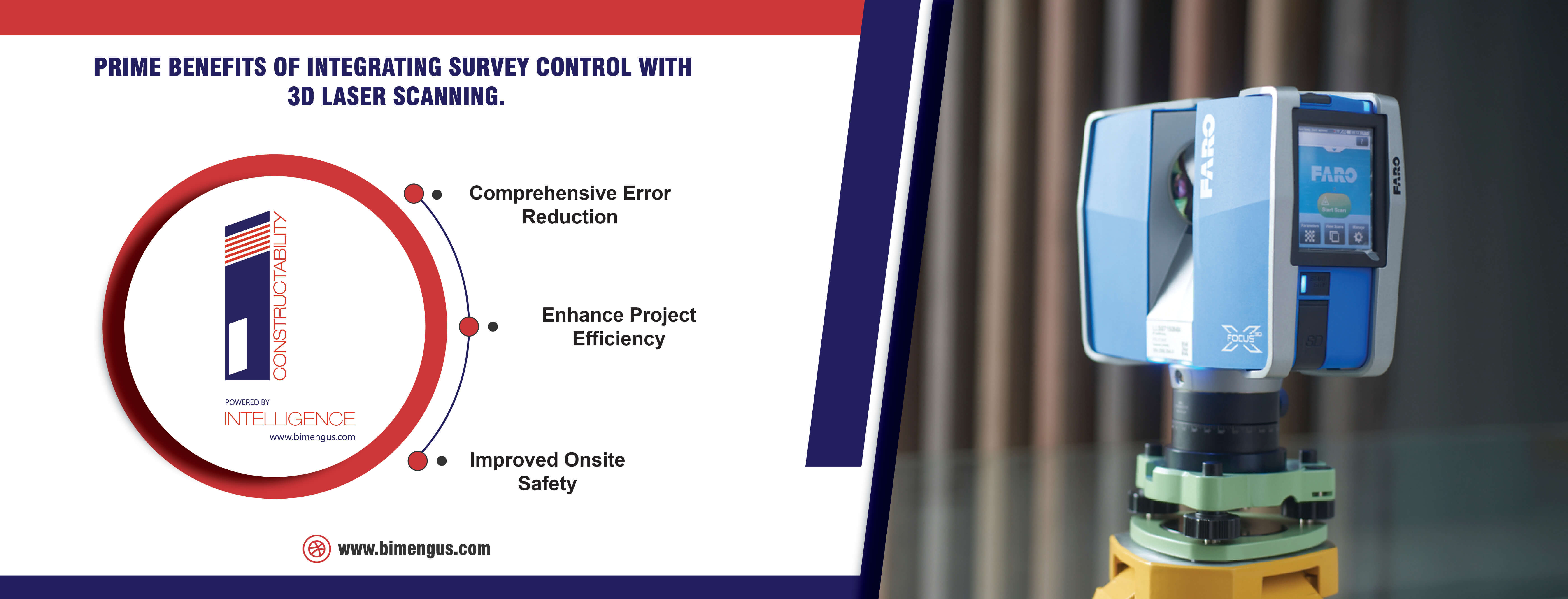

Prime benefits of integrating Survey Control with 3D Laser Scanning.

Comprehensive Error Reduction – the integration of 3D Laser Scanning with Survey Control helps project stakeholders mitigate cost and time errors. The adoption of Laser Scanning early on in the project helps identify and resolve potential issues that create delays and low productivity. It also helps project owners avoid miscommunication and costly fines due to project delays. Designers, engineers, modelers, and surveyors can record, document, and model with accuracy and required project specifications. When Point Cloud Data is overlapped on the model, it tends to improve the overall performance and profitability of the scan.

Enhance Project Efficiency – 3D Laser Scanning is project and labor efficient. Project teams can leverage quick point cloud inputs, whilst Surveyors, GC’s, and Owners can reduce survey time by 70%. With enhanced time savings over traditional methods, teams and stakeholders can leverage scan and model accuracy through BIM processes and technology.

Improved Onsite Safety – it improves safety capabilities for surveying from a remote site or location as surveys can be challenging in terms of site terrain. This mitigates the risk of surveyors facing injuries that challenge owners and stakeholders with accident insurance, labor reduction, and potential fines.

Ensure best practices for 3D Laser Scanning with Survey Control.

When outsourcing or considering 3D Laser Scanning processes and technology, it is crucial to examine best practices for a higher ROI. By considering these, Laser Scanning becomes easier and quicker.

Improve onsite and offsite communication and collaboration – projects perform better and become more efficient when onsite and offsite teams or workflows connect effectively. Reviewing offsite and onsite workflows helps project stakeholders make informed decisions and produce high-quality project deliverables.

Scanning targets or objects need to be strategically onsite – scan objects or targets need to be placed strategically to document accurate scans. Precise registration requires three or more reference points. Taking scans for objects that have different elevations or taken wide apart produce better scans as it gives the scanner greater numbers of points. Scans taken in a single line make it challenging for the scanner and surveyor to classify spatial relationships.

Perform a thorough QA/ QC of the scan – thoroughly verifying, measuring, and registering scans helps produce better-scanned deliverables. This is where Survey Control helps projects with large data-sets. Surveyors can face problems in the automated registration or targeting process. Cleaning up scans by removing noises requires target validation by comparing onsite objects and scans. Investing some time in removing scanned noise before sending it out to modelers helps reduce errors, rework, and delays.

Now that you’ve understood the benefits and leading industry practices, you need to select a Survey Control technique for Laser Scanning.

Significant factors to evaluate options include –

Test system integration and interoperability – it is crucial your laser scanning solutions integrate well with existing processes and technology. You also need to make sure, the software supports BIM interoperability for collaboration, data transfer, and scalability.

Does it comply with your project or organizational goals? As these solutions can be expensive, firms need to understand their scanning needs. These requirements can be listed as scanning, processing, and handing-over deliverables for 3D visualization and as-built data.

Check the reputation of the Laser Scanning provider – as design and construction projects can be large-scale and time-consuming, it is important to select a provider with a good reputation.

Select a provider that offers support and training of the Laser Scanning software and hardware – choose a provider that offers long-term support and training so that workflows and processes can be streamlined.

Test the Laser Scanning System – test the system in the field for a real-time experience, usage evaluation, and various parameters.

Wrapping it up.

Partner with an experienced Laser Scanning provider to capture, process, and hand-over physical spaces in a digital format. The right Laser Scanning services give construction firms the capability to capture, analyze, and manage building scans or scans converted to BIM models.