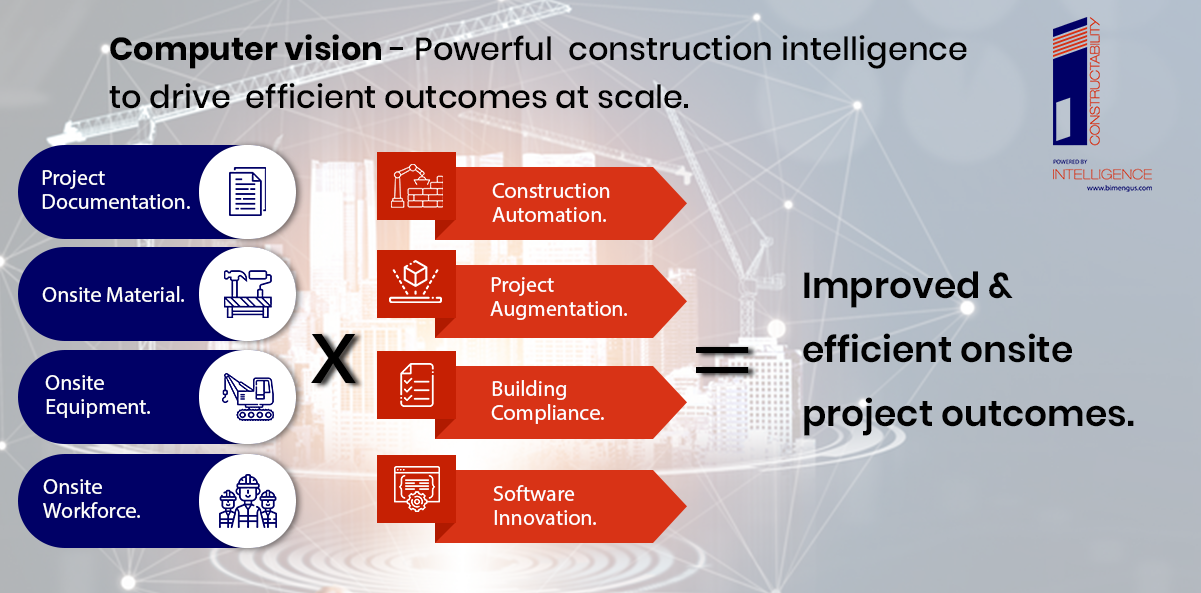

Construction vision is changing the landscape of onsite construction. This technology allows onsite construction personnel to measure and analyzes objects in real-time and real life. Computer vision tools and technology use digital media like images and video to calculate the incalculable. Construction sites can be complex and high-risk at the same time.

Onsite challenges.

Onsite personnel faces a myriad of challenges that include accidents, unsafe conditions, quality, and snag checks, and onsite monitoring. In the present, computer vision has become a crucial application that draws the true capabilities of Artificial Intelligence (AI) and Machine Learning. This technology has immense potential in the construction industry based on object identification and recognition. It can also be integrated with BIM processes and construction management software to assess work comparisons, or evaluate video data in real-time, identifies onsite work quality, and deviation from set work plans.

A snapshot of computer vision benefits.

As mentioned earlier, computer vision is extremely beneficial to monitor site safety through real-time camera footage, hardhat detection, vest visibility, onsite goggles, etc. required for personnel working at high-altitude projects. The AI in computer vision can assess the absence of onsite gear on workers, evaluate threats, etc. and caution site managers to take the necessary steps and avoid onsite accidents.

Live streaming data or footage from a camera, drone, or laser scanner can be evaluated to check for defects and quality problems. This identification can help the design team make changes in the BIM model, or resolve As-Built challenges to save project time, money, and resources. Computer vision can also help build 3D models to monitor progress, manage autonomous technology or equipment, etc. to monitor site activities.

Optimized and efficient job sites.

Comprehensive inventory monitoring can be achieved by using HD cameras or aerial laser scanners. By analyzing data received from these devices, project managers and contractors can track and modify analytics into actionable insights for ongoing job site processes. Computer vision has great potential to optimize processes, mitigate bottlenecks, check for worker travel routes, and improve construction material inventory.

Computer vision integrated with machine learning can reduce onsite idle hours leading to reduced project delays. Under-utilization or Over-utilization of resources can be reduced, actionable insights can be leveraged, and real-time intelligence can be deployed.

Computer vision can drive data analysis through the cloud to cut down on costs. Progress tracking with 3D BIM models can help estimate project completion timelines, planned vs actual progress, and more.

The top 5 applications of computer vision include :

#1. Monitoring compliance for Personal Protective Equipment (PPE)

Computer vision can help enforce onsite protocols to make the job site safe. AI and Machine Learning tools can identify workers to make sure onsite personnel wear PP equipment like visibility jackets, hardhats, shoes, masks, etc. Real-time and real-life identification of objects monitored through visual devices like drones, HD cameras, laser scanners, etc. helps notify security officers and construction managers of a job site PPE breach. Image and video analysis can help achieve perpetual site monitoring to reduce rework and project delays.

#2. Track material proportions

Computer vision can help project stakeholders analyze existing material requirements with periodic notifications. Alerts generated in advance can help resolve under-utilization and over-utilization of material quantities which can mitigate project delays and site coordination problems.

#3. Optimize the efficiency of onsite personnel

Worker movement routes are crucial to identify an onsite flow. Patterns observed in movements can help onsite construction managers and personnel create shorter travel routes, mitigate activity bottlenecks, and improve job site material warehousing.

#4. Quantify manual-cycle timelines

Constant and real-time identification of each onsite worker can create a large database to measure the task duration of every onsite worker. Similar to 3D BIM model progress monitoring, computer vision can help quantify manual timelines to estimate onsite task completion.

#5. Prevent unapproved access

Unauthorized access can be a huge onsite threat, ergo, computer vision tools and software help identify unidentified personnel onsite and other restricted areas. This is achieved by scanning vehicle license plates, facial recognition, identification cards, etc.

Wrapping it up.

It’s time the construction industry leverages complete computer vision to achieve the real-time object and event detection through images and video from the cloud. Explore a myriad of computer vision service offerings for image, video, and face recognition to achieve lean construction through site intelligence and insights. Reduce onsite waste and achieve complete worker and activity transparency through onsite progress tracking. Draw immediate action from insights to reduce onsite rework and project delays.

Visit Us:- www.bimengus.com/