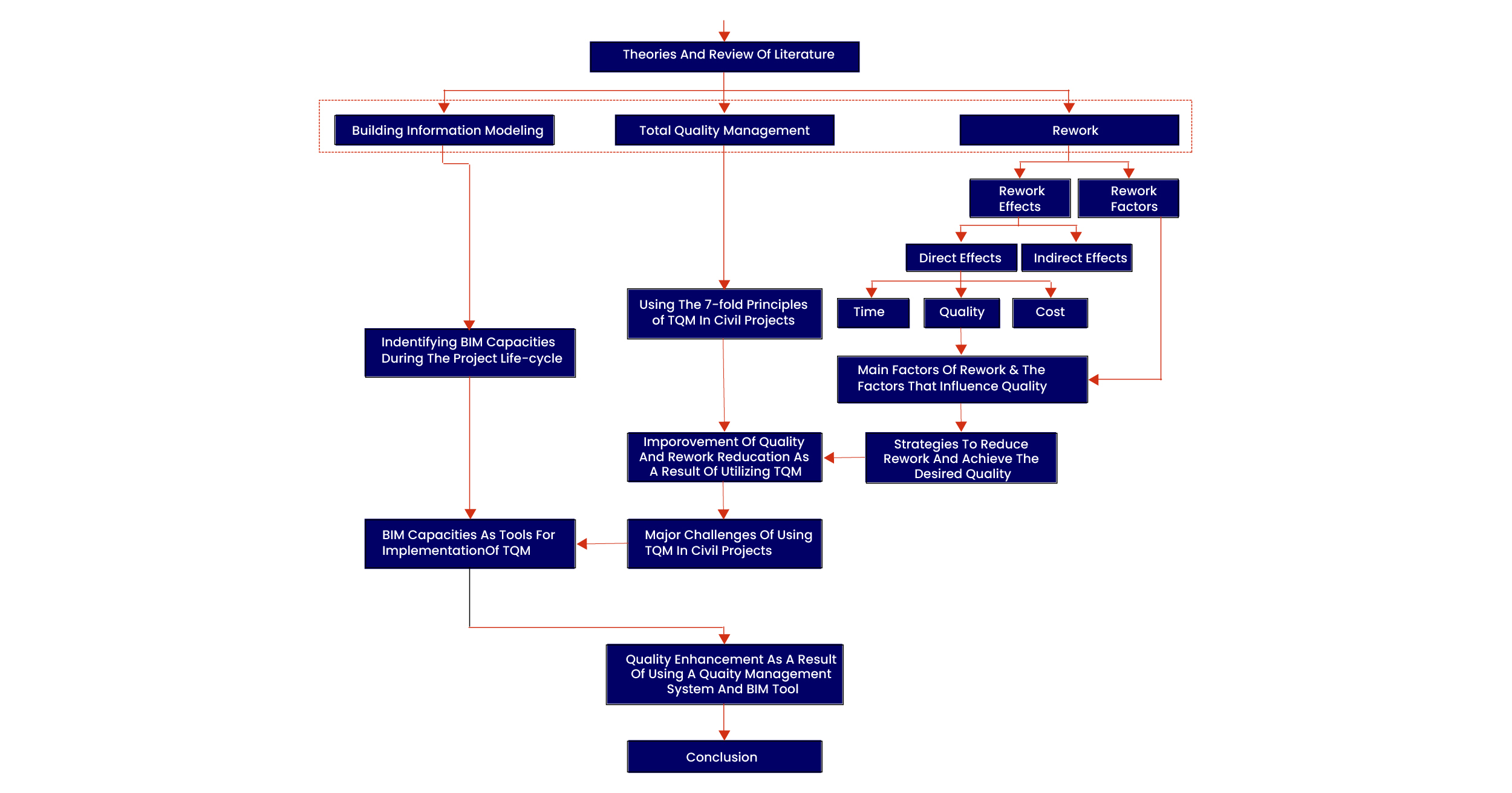

One of the most crucial challenges that have affected the construction industry is “Rework”. It has a direct impact on cost, time, quality, people, and other criteria that facilitates project success. Consequences of continuous rework create considerable resource losses, material waste, and stakeholder investment.

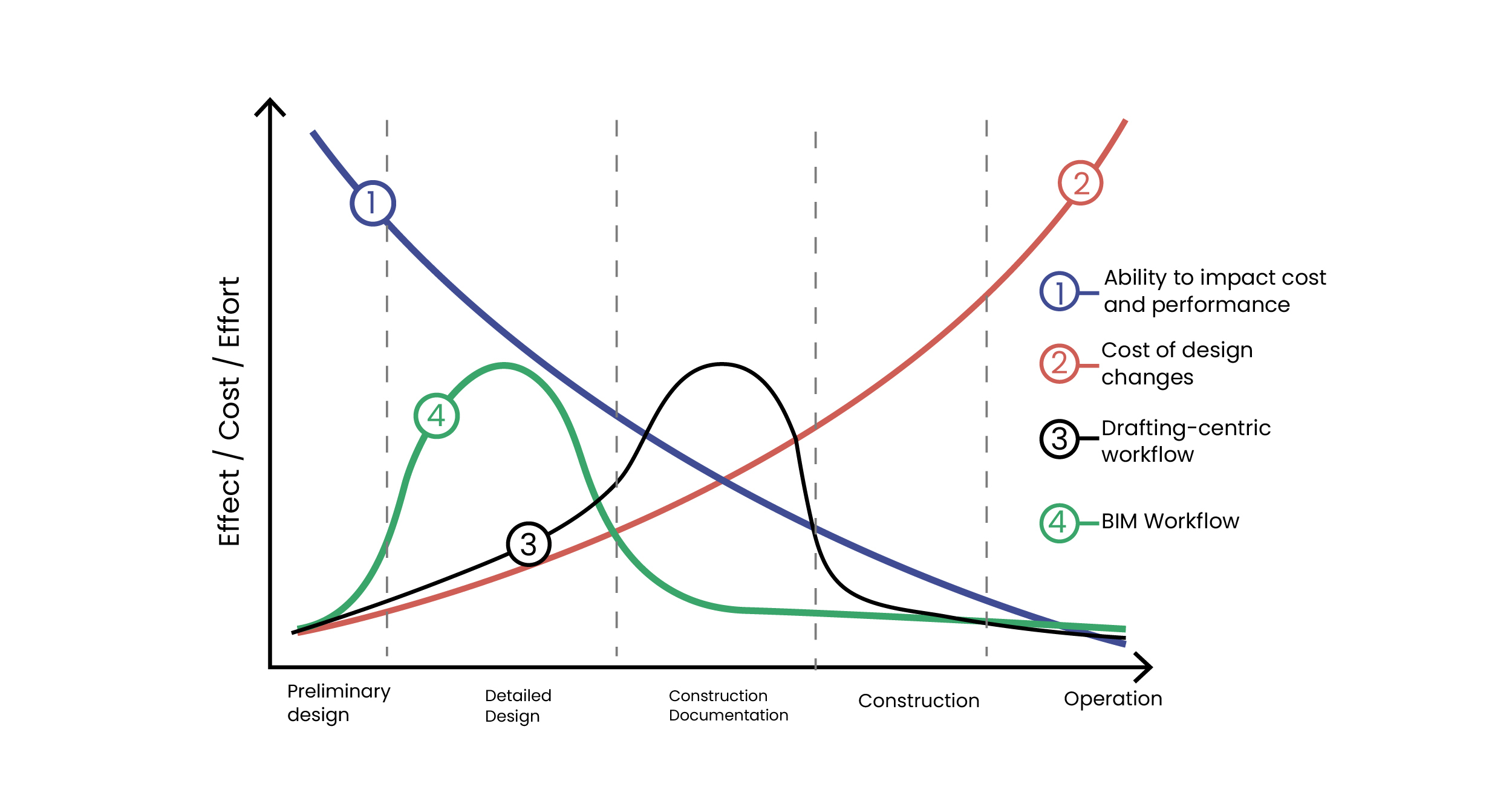

The adoption of meticulous designing and planning in the presence and awareness of clients helps fuel effective communication and utilization of optimized systems. The elevated use of BIM on a global level through various processes, tools, and software has helped reduce project inconsistencies and errors. This shift has helped architects, engineers, contractors, owners, and other stakeholders realize the full potential of BIM. It has pushed project stakeholders to apply TQM or Total Quality Management Models through BIM.

Managers need to identify the most influential components that can lead to rework and their effects on the project. A few factors that cause rework can be illustrated as follows.

- Design Errors

- Changes in client orders

- Poor project definition

- Insufficient project planning

- Weak communication leads to inefficient design

Key processes, tools, and technology that can reduce project rework.

- Building Information Modeling (BIM)

- Lean construction techniques and tools

- Modular or prefabricated construction

- Project feasibility assessment

- Project construction and procurement based on effective communication and collaboration

In simplicity, Rework is defined as “ an unnecessary effort of re-doing processes or activities that were done or implemented incorrectly in the first attempt.”

The cases of rework include – design errors, constant construction changes, constructability errors, and eliminating or expanding the scope of the project. The effects of rework can be significant, it has direct or indirect effects on team and project performance.

Direct effects of rework

- Time overruns

- Cost overruns

- Additional material for rework

- Cost of additional supervision

- Reduction in project quality

- Negative environmental impact

Indirect effects of rework

- Profit reduction

- Shallow team morale

- Team conflicts

- Physical stress

- Mental exhaustion

- Loss of future opportunities

Significant factors that influence rework

- Nature of the construction project

- Inefficient material procurement

- Project complexity

- Lack of coordination between various stakeholders

- Poor communication between offsite and onsite teams

- Uncertainties due to weak information

- Client changes

- Delayed material delivery & low material quality

- Defective construction

- Errors in design

- Lack of clear project scope and processes

Primary solutions to reduce rework

- Effective use of project teams or workforce

- Adoption of new technologies to enable constant improvement

- Working on a client- centric model to reduce errors

- Assigning greater focus on the design process

- Managing project suppliers better

- Support project standards

Total Quality Management

Total Quality Management or TQM is a management technique that requires the participation of every stakeholder to drive quality. TQM works on the principle wherein profits follow quality. TQM is adopted in construction to achieve high project standards for complex buildings. The world of construction can cause delays and errors, and thus TQM is applied to construction for clear conception, better visualization, achieving project goals, and leverage productivity.

Basic steps in implementing Total Quality Management (TQM).

- Build an approach towards TQM

- Need to achieve a quality commitment from the client

- Prepare a project quality plan at all project levels

- Take necessary steps to ensure continuous project improvement

- Measure and review quality plans and performance

The need to adopt Total Quality Management (TQM).

- Lack of project records for experience, decisions, etc.

- Low project execution quality

- Lack of workplace necessities

- Lack of workforce participation

- Increase in construction cost due to rework

- Material waste in construction

Striking benefits of Total Quality Management.

- Reduction in cost of quality

- Higher client satisfaction

- Lesser corrective work

- Reduction in project delays

- Better relationship with suppliers and sub-contractors

Seven primary features of Total Quality Management (TQM).

- The commitment to efficient project management

- Perpetual attention to project teams and clients

- Efficient use of project workforce & teamwork

- Continuous project improvement at various phases

- Consider material suppliers as project stakeholders

- Secure and control the quality

- Train the HR team

Key BIM capacities during various project lifecycles.

- Parametric objects or construction members

- 3D modeling enhanced visualization and reduction in claims

- Better change management

- Accurate fabrication based on preconstruction

- In-depth documentation during handover

- Construction simulation and project time savings using 4D

- Precise Quantity Surveying & 5D cost estimation

- Better equipment management for planning, renovation, and maintenance

- Collection and record of information for Facilities Management

- Sustainable project design and construction

- Higher design coordination for greater constructability

- Enhanced onsite safety

- Early conflict detection

- Improved readability and BIM translation for better accessibility

- Quick prototyping and response to design changes

How BIM reduces rework and enhances quality through TQM.

As various project stakeholders like architects, designers, engineers, contractors, etc. have their points of view, it is important to build a shared aspect for project optimization is crucial. BIM enables complete and effective communication and collaboration between various stakeholders.

- Enhanced communication and collaboration help in the reduction of plans and document exchange

- It also improves the accuracy of content in these documents

- BIM quickens project design, execution, and processes in a virtual building landscape thereby delivering an accurate 3D model

- BIM models are parametric models that can be accessed anywhere, and anytime, and analyzed by various stakeholders. This improves the decision-making process

- With every piece of building information infused in a model, problems are detected and resolved before actual construction

- Based on TQM, a BIM model is the most credible source of information at various project stages

In summary,

BIM has an innate relationship with enhancing and promoting construction quality measures. BIM serves as a great tool to overcome various rework challenges, and achieve Total Quality Management (TQM). It helps the complete design and construction team stay on the same page with ready information, improved communication, and a greater focus on positive outcomes.

Visit Us: www.bimengus.com