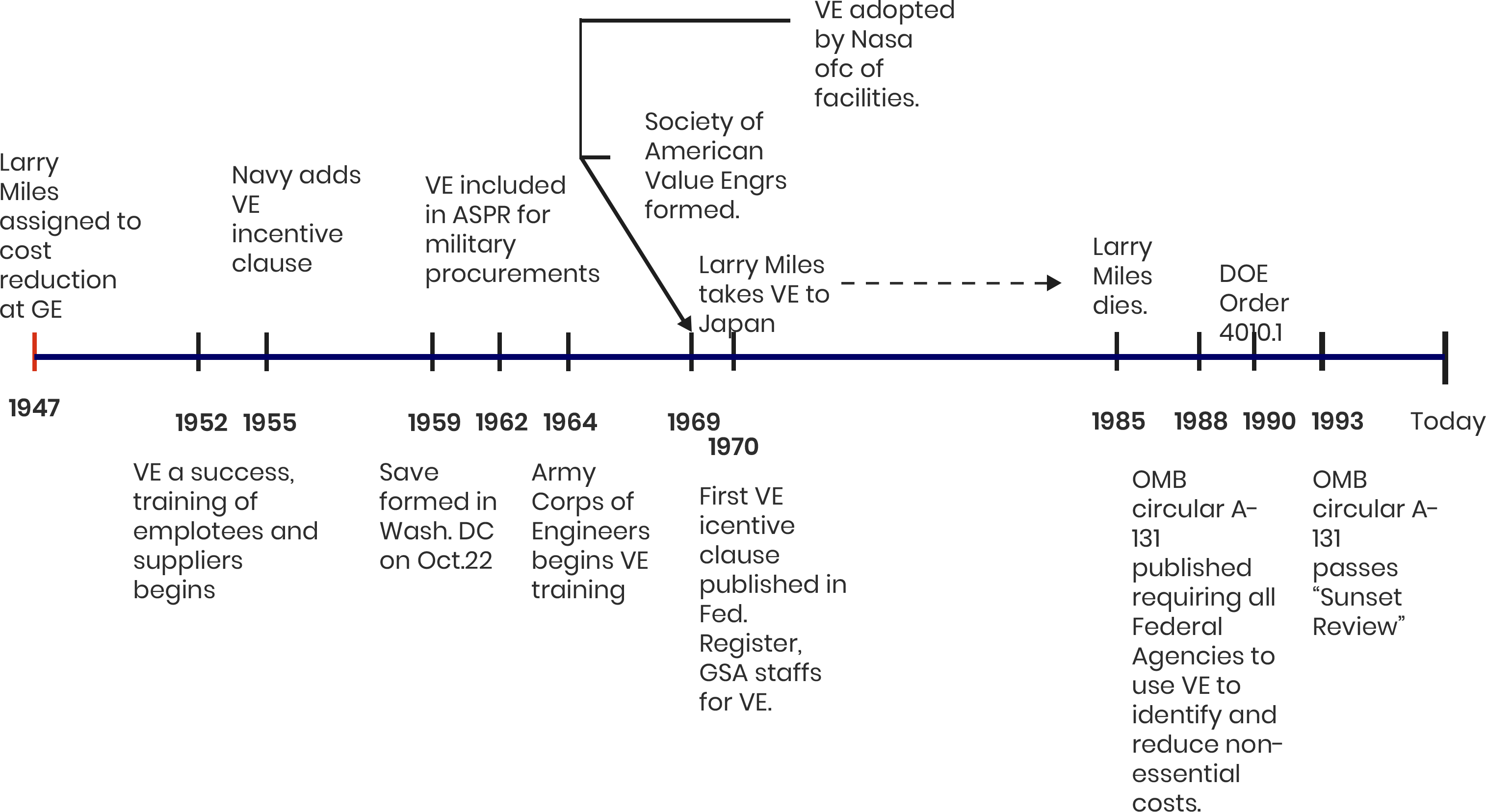

- The concept of value engineering was developed by Lawrence Miles

- This concept was devised as a result of the material shortage of certain finished products during the Second World War

- The only problem was the manufacturing process was running at full capacity through the shortage of goods.

- Lawrence Miles worked for General Electric or GE

- As he was not able to obtain any replacement material, it was quite necessary to obtain materials at maximum capacity

- Value engineering began with a team-based approach.

- As it was more inclined towards engineering, the term “value engineering” was apt

- Instead of value engineering, value management was adopted in a broad and higher-order description

- Value Management (VM) – was defined as a larger spectrum of value techniques

- Value Planning (VP) – was defined as the planning phases of the project

- Value Engineering (VE) – techniques applied during an engineering phase of the project

Value engineering involves various parameters viz.

- Identify various elements of a product or service

- Analyze functions of an element

- Delivering alternate solutions for a function

- Assessing various alternate functions

- Allocating costs to alternative solutions

- Developing alternatives to drive high success rates

What is the definition of Value?

Value can be defined as product, service, or project performance. A good value product can be taken as a product with good performance.

What is the meaning of Value Engineering?

Value engineering deals with focusing on a product or service at the most competitive pricing.

Value engineering deploys a combination of analytical and creative techniques to identify other ways to achieve objectives.

Value analysis or value engineering tends to make the product or process effective and profitable through the initial design phase. It should be noted that the technique of value engineering should never compromise product or service quality.

Areas of application

- Automotive

- Aeronautical Engineering

- Civil Engineering

- Defense

- IT R&D

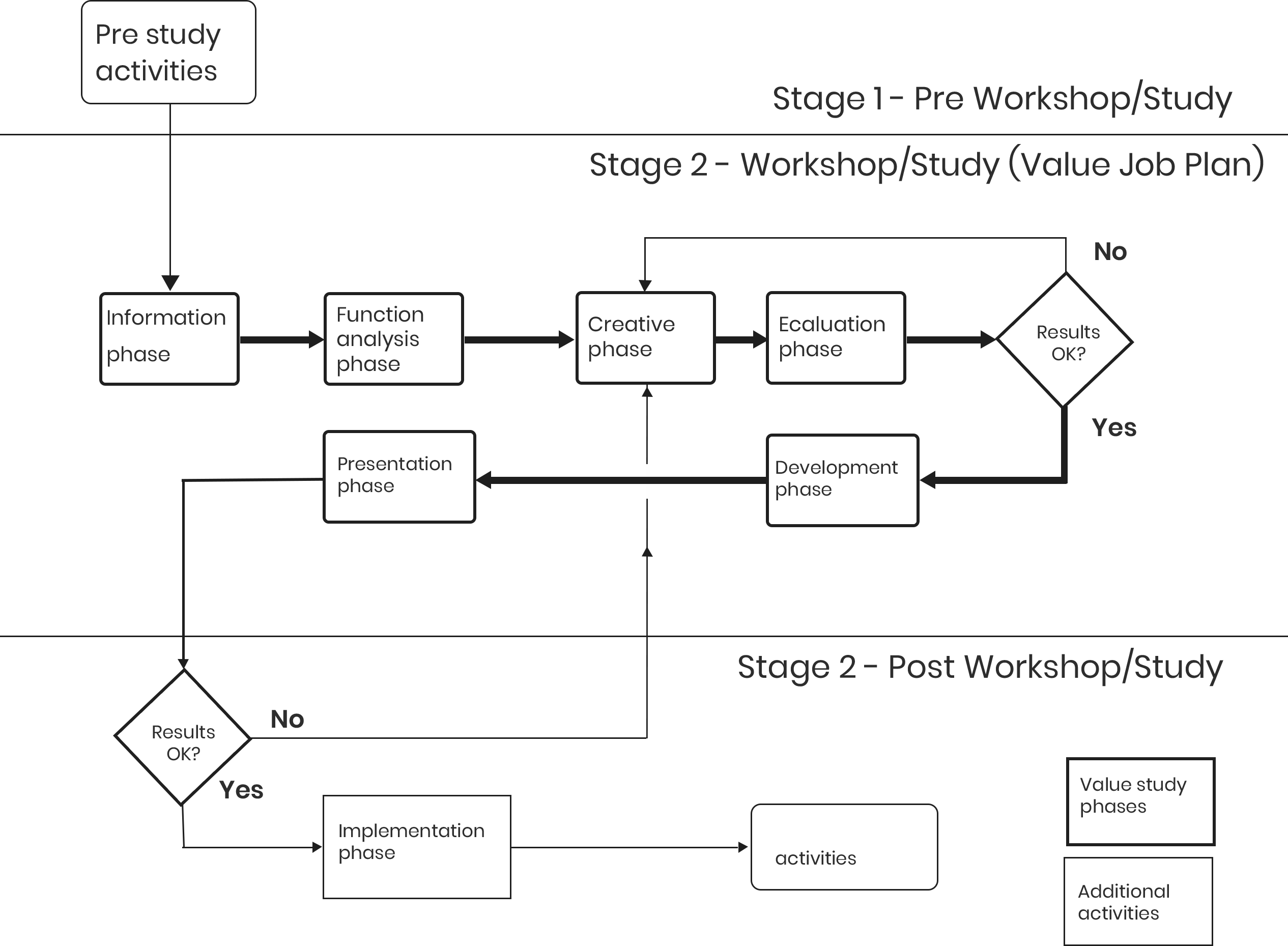

The Value Engineering Job Plan

The VE phase consists of the –

Pre – Study

- Collect User Attributes

- Create data file

- Determine various factors

- Study the scope

- Build various data models

- Evaluate team composition

Value Study

Information Phase

- Finish Data Package

- Modify the scope

- Who are the owners?

- What is the requirement of these individuals?

Function Analysis Phase

- Function analysis is based on identification, classification, cost, value index, and study.

Creative Phase

- Quantity of ideas by function

Create a spectrum of ideas with the widest possible rang

Evaluation Phase

- Select and rate alternate ideas

- Best ideas will be used for the development

Development Phase

- This phase focuses on development viz. benefit analysis, data packages, implementation plan, and final proposals

- Recognize unique ideas

- Support and perfect your ideas

- Prepare an accurate cost estimate

- Analyze the risks

Presentation Phase

- Present various reports viz. Written and Oral

After Studies

- Complete the following changes

- Implement the changes

- Monitor the project status

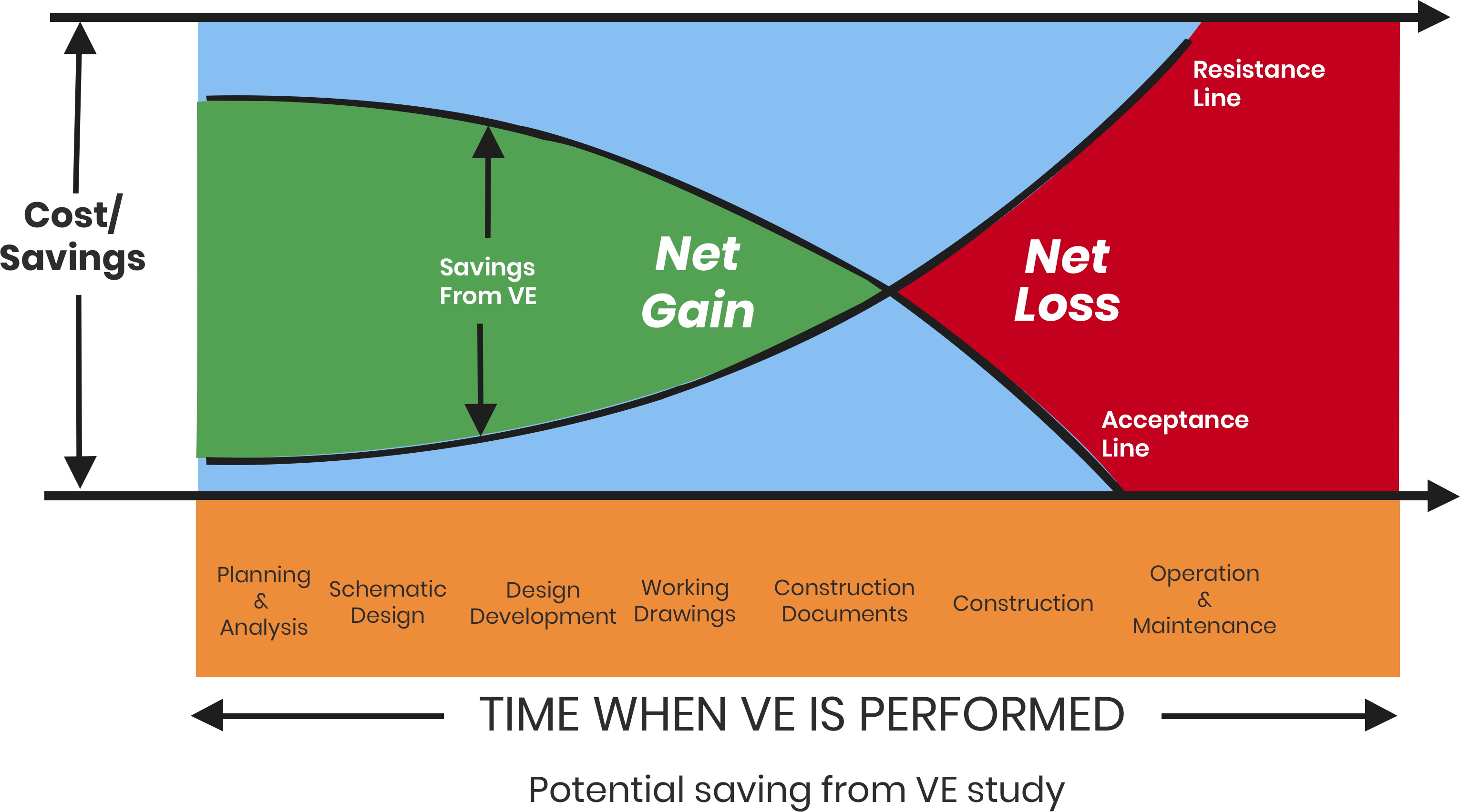

Significance of Value Engineering in the Construction domain

- The value aspect is measured in terms of cost and performance.

- It can also be measured for other aspects like time, productivity, energy, etc

- This methodology is also applicable for construction projects and other soft areas viz, construction processes, healthcare, etc.

- Value engineering for construction projects like buildings, factory construction, sewage plants can be applied on a project-to-project timeline

- Every construction project is a one-time capital project, and value engineering must be applied in the initial phase of the design phase

- If there are changes in design, then it can be achieved through lesser redesign, lower implementation cost, schedule impacts, and more

- When value engineering is applied to construction engineering, it has clear benefits from a development point of view

- It aims at increasing value based on cost and time

- Maximizing a project function and reducing cost generates a “good value” for clients and developers

- In the design phase, the project team reviews the proposed project and performs functional analysis, defines key criteria, and provides alternative solutions

- The value engineering process consists of a workshop that includes the integration of –

- Information – Gather information during the initial phase viz. project objectives, key criteria, and defining value

- Speculation – Maximize function whilst reducing operating cost

- Evaluation – Brainstorm ideas that can or cannot be used

- Development – Workable proposals created on ideas that have passed the evaluation phase

- Presentation – Making a final presentation of the findings

Reasons for increased or poor costs and increased quality

- Information inadequacy

- Presence of temporary conditions

- Inaccurate findings or beliefs

- Very few ideas

- Technology changes

- Time Constraints

- Lack good coordination

BENEFITS OF ADOPTING VALUE ENGINEERING FOR CONSTRUCTION PROJECTS

REDUCTION IN CONSTRUCTION COSTS

Construction projects have high function costs, these costs need to be reduced without sacrificing construction quality or using low-quality materials

If materials are old, then better quality materials have to be adopted with an economical solution.

Finishing the project before the time

Finishing the project on time can leverage significant cost reductions. It is not necessary to boost the production speed, but the process can begin earlier.

Mitigating Mistakes in Project Drawings

Value engineering uses 3-Dimensional projects to maintain the quality of the project. Projects with errors can pose a negative value and are not suitable for an application, whilst projects with no or minimalistic errors are categorized as a positive effect in comparison to a negative effect. A 3-dimensional project prevents errors to be mitigated in the architecture phase itself.

Visit Us :- www.bimengus.com