Summary

- One of the most impactful in the construction industry is digital twins

- Improving the analytics capabilities of BIM is a key feature of Digital Twins

- Virtual construction models can clone every detail of a given building

- Individual components and specific materials are detailed with in-depth information

- Depth of data in these models is crucial and valuable for construction firms

- Detailed digital models can enable better information based on various scenarios in the field

- It is the most detailed model as stakeholders can leverage a virtual copy of the real-world structure

- Construction companies use digital twins to build detailed models of the existing object or structure

- Various simulations can be tested viz. natural lighting, fluid dynamics, HVAC systems, etc.

- Digital Twins convey a greater process-oriented characterization through a combination of IoT, Artificial Intelligence, Software Analytics, and Machine Learning

- Digital Twins are also deployed to leverage better modifications, maintenance, and operations

Transformational advantages of a Digital Twin

- BIM and Digital Twin strategies are built on common principles

- Improve process visibility and support project planning

- Unifies information from initial design for manufacturers, component selection, onsite delivery, etc. to maintenance and operations

- Used in site construction to constantly update information

- Reduction in site visits by stakeholders based on information stored & shared in the digital model

- Manage and minimize change orders based on smart design & project planning to reduce the impact of schedule and budget on the project

- Cost savings by avoiding project rework through data collected by sensors from the job site and updating the As-Built model

- Improved collaboration based on a two-way information flow from the job site to the twin, and the twin to the job site

- Every team stays on the same page with access to real-time data to make informed decisions

- Improved worker safety through real-time tracking worker tracking in unsafe zones based on sensors installed in critical areas to monitor stress and load

- Validate project deliverables and constructability through digital twins for reliable maintenance and operations

- Monitor building safety with sensors installed in the structure to transmit data to the digital model

- Test virtual sequencing and logistics to reduce construction and onsite costs

- Optimize operational performance and sustainability

Resource Administration

- Build an information tunnel between the field and back-office

- Automated data distribution helps resolve resource allocation problems and labor cost bottlenecks

- Jobsites become more affordable and efficient

High-quality and value-packed construction deliverables –

- High-quality deliverables help owners perform structural enhancements

- Offers invaluable insights on perpetual building operations

- Clients can leverage DTs to optimize projects in the future

Connected construction –

- Utilize and share information from a centralized platform

- Update 3D BIM models with automated and constructible information

- 3D models can integrate dimensions, model details, etc. to maintain model and data integrity

A practical example of a Digital Twin.

- Consider multiple high-rise structures working on a centralized HVAC system

- If any element of the HVAC system were to malfunction or perform below the required efficiency, sensors would send data to the digital twin and alert maintenance personnel at the earliest

- This would reduce time-consuming and costly repairs of the HVAC system

- It would also enable greater resident safety and staff safety depending on the type of project

- Owners can leverage a better understanding of their buildings or facilities & manage them accordingly

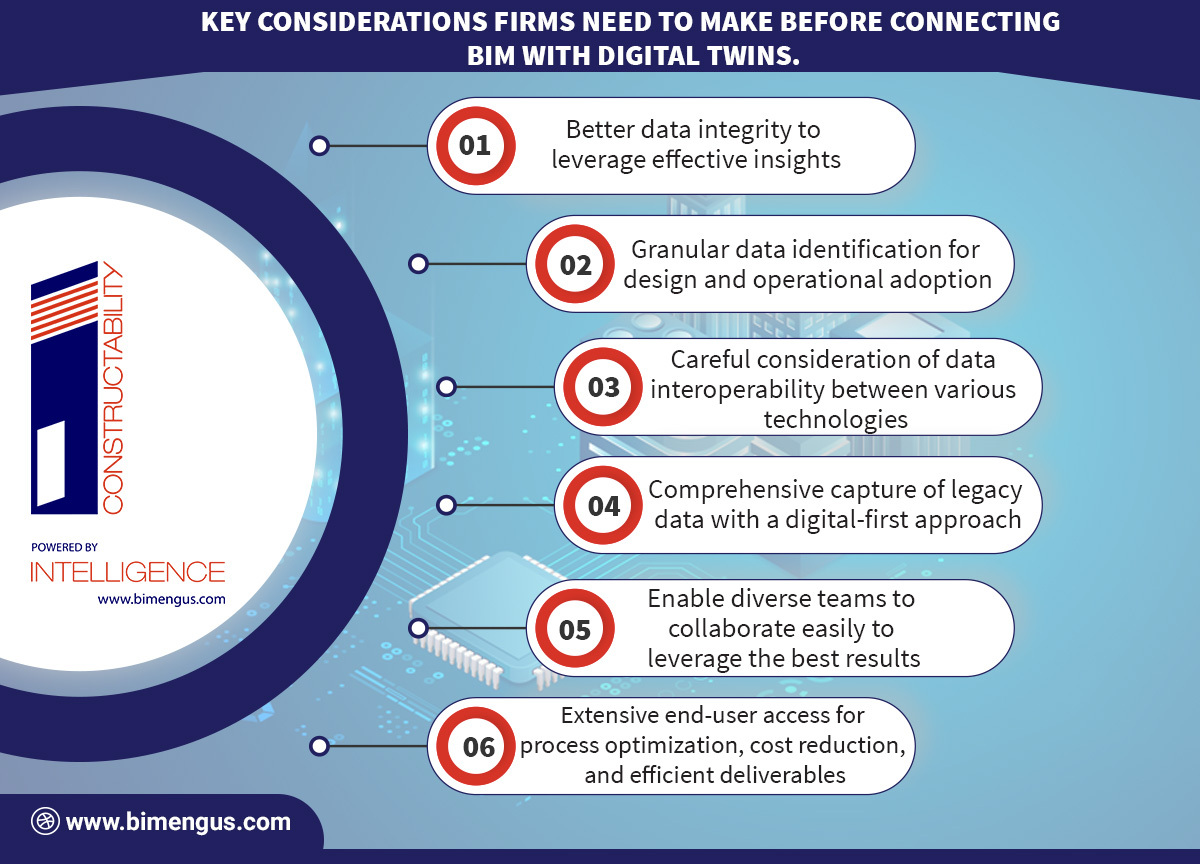

Key considerations firms need to make before connecting BIM with Digital Twins.

- Better data integrity to leverage effective insights

- Granular data identification for design and operational adoption

- Careful consideration of data interoperability between various technologies

- Comprehensive capture of legacy data with a digital-first approach

- Enable diverse teams to collaborate easily to leverage the best results

- Extensive end-user access for process optimization, cost reduction, and efficient deliverables

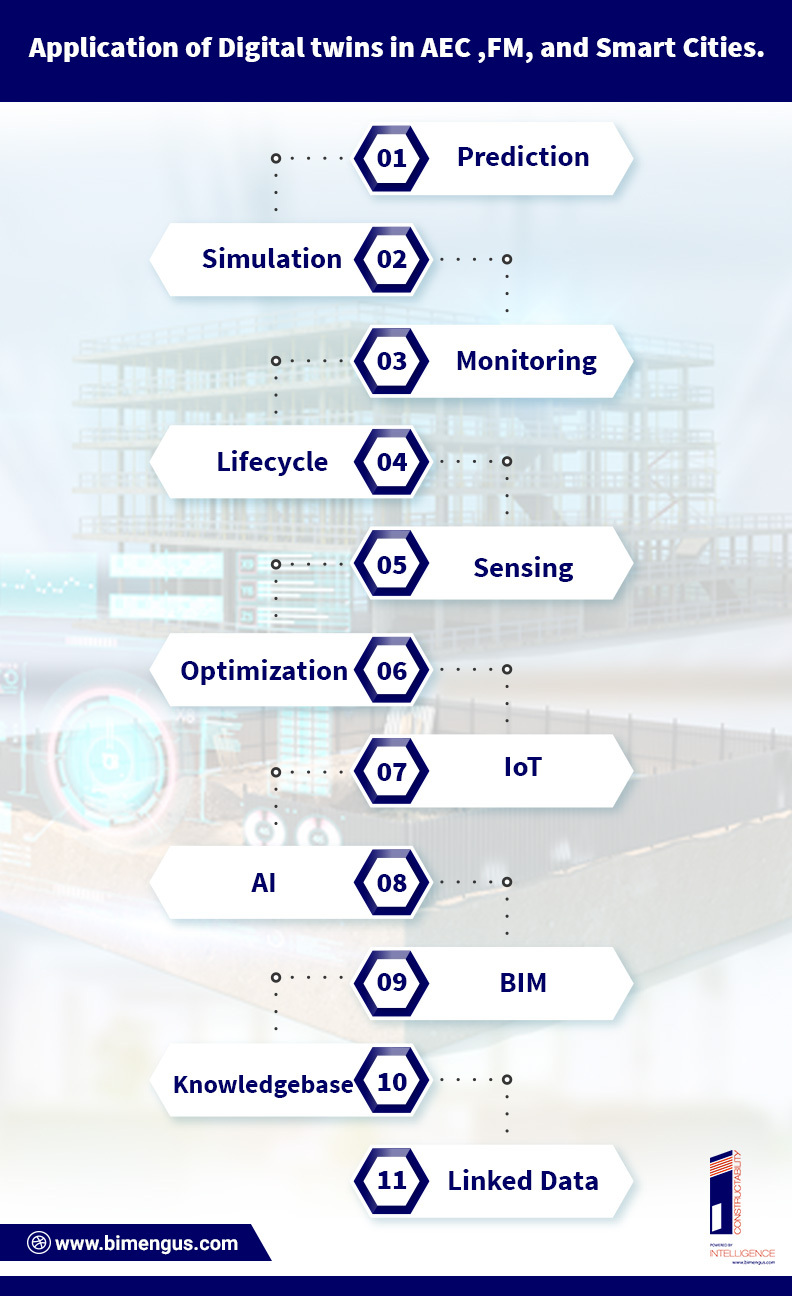

Application of Digital twins in AEC and FM, Smart Cities

- Prediction

- Simulation

- Monitoring

- Lifecycle

- Sensing

- Optimization

- IoT

- AI

- BIM

- Knowledgebase

- Linked Data

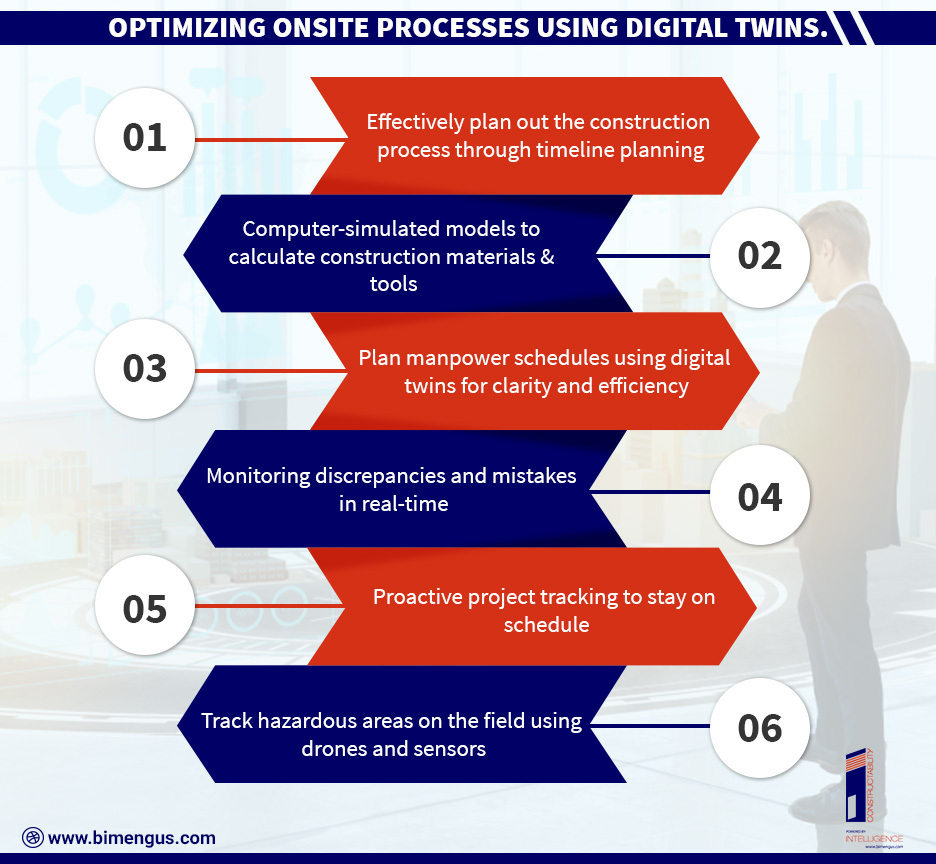

Optimizing onsite processes using Digital Twins

- Effectively plan out the construction process through timeline planning

- Computer-simulated models to calculate construction materials & tools

- Plan manpower schedules using digital twins for clarity and efficiency

- Monitoring discrepancies and mistakes in real-time

- Proactive project tracking to stay on schedule

- Track hazardous areas on the field using drones and sensors

The process to build a Digital Twin

- Select the right software to build a digital twin viz. Dassault Systems, Procore construction, etc.

- Build the model before construction by recording a digital twin in a computer model

- Setup data-collection tools or devices like sensors, smartphones, IoT devices, etc.

- Analyze and adopt data during the construction process

Transformational breakthroughs in Modular Construction with Digital Twins

- Adopting Digital Twins for Modular Construction can help reduce costs and save construction time

- Simulating onsite assemblies of manufactured components can be simulated to prevent rework and save construction time

- As DT’s have begun playing a major role in modular construction, they can be scaled with these steps:

- Build generative design instead of traditional 2D drawings – helps speed up projects and saves time

- Analyze component performance before building – digital twins help manufacturers analyze component tolerances through expansion, deformation, etc.

- Make data or information accessible to every team and project stakeholder – leverage the power of design algorithms with technical factors to avoid silos

- Capture and analyze data from the modular product – integrating sensors into fabricated components helps designers understand the component performance

Conclusion

- The construction sector can significantly benefit from adopting Digital Twins in the construction sector

- As BIM tools evolve, they need technology that can help unlock new levels of data visibility and coordination

- Improving construction requires a true CDE that not only helps people in the field but augments design and operations as well

- Perpetually improving everything that can be interacted with by combining multiple data sources will be the next step in sustainable construction.

Contact Us: – 703-994-4242

Visit us: – www.bimengus.com