The relative cost of Laser Scanners has significantly reduced, and its ease of use has improved as well. The accuracy of gathering 3D data generated by the use of effective technology has moved across a wide range of applications.

High-precision, robust, and portable laser scanners enable an advanced ability to create highly-detailed graphic and dimensioned representations of large facilities or structures. As-built documentation for complex structures like refineries, production facilities, airports, power plants, historical monuments, and healthcare facilities requires the application of laser scanning to design, build, renovate, or extend these facilities.

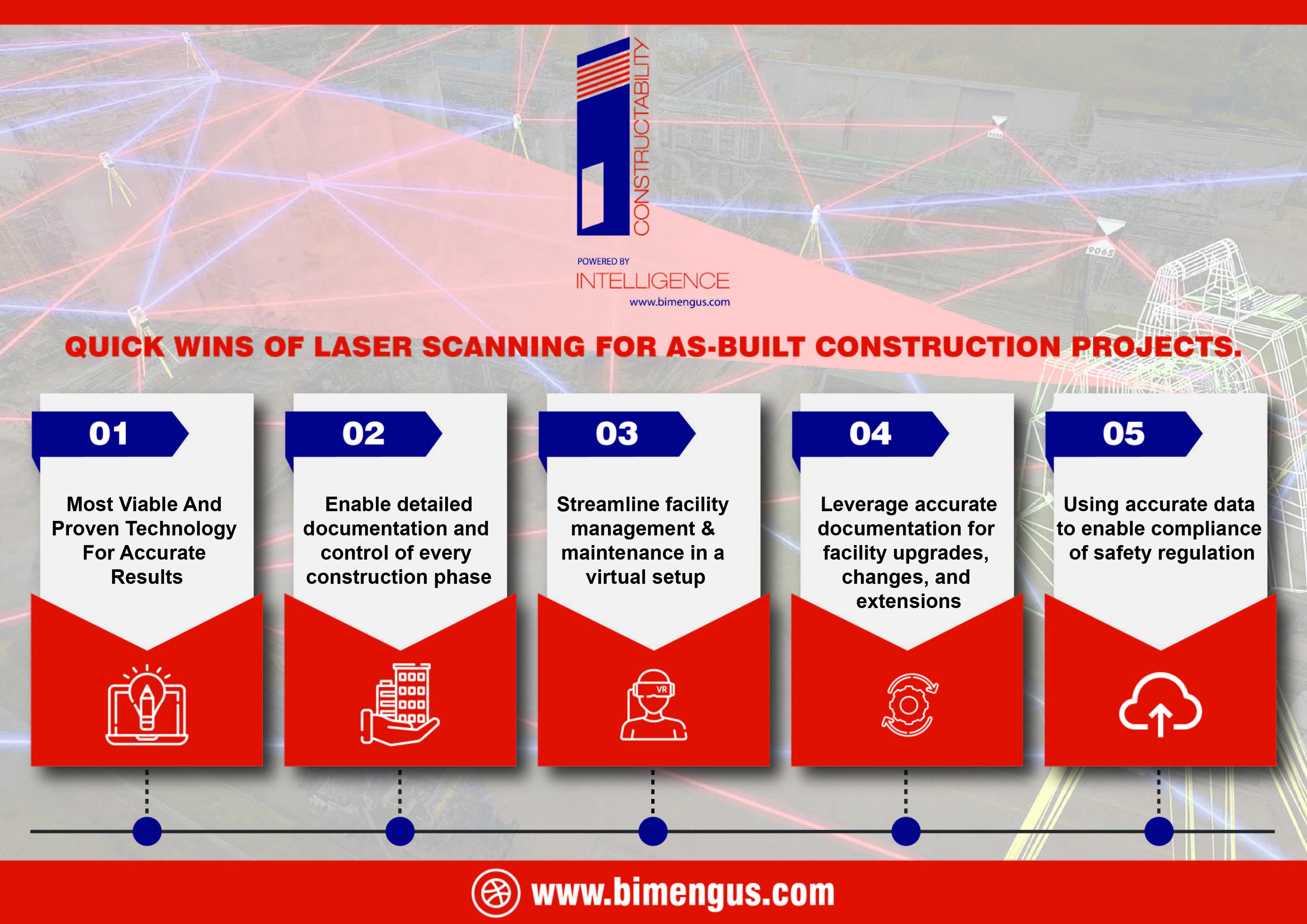

Laser Scanners are a proven technology for accurate results.

Laser scanners send out a laser beam that is reflected off a structure or facility being scanned. The reflectivity and distance of each bounced-back signal are measured and recorded building a dense and detailed point cloud. Modern laser scanners have the tools and technology to measure thousands or millions of co-ordinates every second creating an accurate as-built record.

This technology allows precise and comprehensive detailed 3D models of the most complicated facilities. With a scanning routine, the collated data allows accurate measurements to be calculated between the scanned environment and scanned points. This captured data can be leveraged with a Point Cloud Configuration or detailed photo-realistic format.

3D laser scanning offers numerous benefits technical and economical benefits in facility design, construction, and operations. This technique can be adopted to guarantee on-site safety and minimize risks for deliverables and maintenance of projects. Laser scanners enable a significant reduction in investments for clients.

3D laser scanner like Faro, Leica, or other scanners has proved to be effective instruments for construction quality control and documentation during construction. Quick detection of discrepancies between designed and as-built performance during the construction process can lead to timely adjustments and avoid clashes or errors.

The adoption of laser scanning guarantees construction performance and quality. Accurate installation of technical equipment in the building or facility signifies harmony with the architectural concept. It also enables reductions in project risks for time-sensitive projects whilst optimizing collaboration & online document sharing. Furthermore, this technology enables comprehensive verification and monitoring of health and safety directives.

Comprehensive documentation and control of every construction phase.

Laser scanners enable complete and as-built documentation that includes photo-realistic images of existing building or facility conditions that are under construction. Clear and updated records promote clear control and monitoring for all the construction phases and build a common database that improves collaboration between various parties.

Precise documentation can be used to update designs, projects, code requirements, drawings, and a myriad of standards. Engineers and project managers can leverage can quicky identify survey differences between the design and actual conditions. With laser scanning running point, it is simpler and less costly to replan on a screen, rather than make changes in the field.

Laser scans reduce possible risks and mitigate cost increases through various project phases. Complex projects with tight schedules can benefit from savings as a consequence of enhanced project sequencing & construction coordination.

Streamline facility management & maintenance in a virtual setup.

Leverage precise and complete 3D documentation to support various activities linked to management and maintenance of structures or facilities. With point clouds converted to 3D models, users can view the position of components, parts, and leverage complete details.

In the advent of problems or challenges, every piece of information can be accessed immediately to enable quick and efficient problem identification.

Leverage accurate documentation for facility upgrades, changes, and extensions.

Facilities often need to be upgraded or extended due to a myriad of reasons viz. technical enhancements, regular updates, latest procurement, etc. Facilities need to manage these changes efficiently to minimize costs or time delays. When work is done on existing facilities, there are discrepancies in the original plant design and actual installable conditions.

Based on 3D documentation, facility operators can identify conflicts between designs and conditions for components like pumps, motors, valves, pipe systems, etc. Geometrical models & photo-realistic images from scan data can be processed through software to explore various design prototypes.

Using accurate data to enable compliance of safety regulation.

Large and complex facilities need increasing levels of safety regulations by clients and governments. These requirements need as-built or as-maintained documentation of structures or facilities. Laser scanning enables high quality and comprehensive documentation that satisfies compliance requirements for health and safety directives.

Various Levels of Accuracy

The specifications prescribe five levels of accuracy for building documentation. These levels are designed to achieve a well-defined and cost-effective scope for the project.

LOA 10 – Upper Range: User-defined – Lower Range: 5 cm

LOA 20 – Upper range: 5 cm – Lower Range: 15 mm

LOA 30 – Upper range: 15 mm – Lower Range: 5 mm

LOA 40 – Upper range: 5mm – Lower Range: 1 mm

LOA 50 – Upper range: 1 mm – Lower Range : 0 mm

Conclusion.

For more information on laser scanning and it’s services for large and complex facilities, click on https://www.bimengus.com/point-cloud-services.php